Lincol Oil Company supply an extensive range of Food & Beverage Lubricants. To view our range please select from one of the categories below!

Safety

All products are registered with the National Sanitation Foundation (NSF) as Class H1 for use where the potential for incidental contact with food and beverage products exists.

- Approved for use in Halal and Kosher food manufacturing.

- Approved by NSF International as Class H1.

- Components approved by the US FDA for incidental contact with food.

- Meets former USDA H1 requirements.

- AQIS Lubricant Type A compliant.

- NZ MAF classification C15 compliant.

- Suitable for use in the preparation of vegetarian foods.

- Not manufactured from GMOs.

- Complies to EU Allergen Regulation 2003/89/EG.

- First production site to be awarded the certification of ISO 21469 in March 2008.

The free LCCP survey

Lubricants are defined as a chemical hazard in food production processes and as such should be part of a company’s HACCP (Hazard Analysis Critical Control Point) audit. To support our customers, Lincol offer a free LCCP (Lubrication Critical Control Point) survey that identifies:

What are the potential risks? Oil and grease contamination of food and food packaging can arise from a variety of mechanical failures, mis-applications and design faults. A few common ones are lubricant carried in compressed air, leaking gearboxes above conveyor belts carrying food product and over-greasing of bearings near food.

What can be done? Before preventative action can be taken, it is essential to take an inventory of each lubricant point where contamination of the food product is possible. Following an LCCP Survey our technical team can make an inventory of each lubricant point and present a preventative action plan based on a clear understanding of your processes.

The LCCP Survey can feed into your HACCP submission verifying that the risk of contamination of the end product from lubricants is minimised and correct food grade lubricants are used in the pertinent applications and in the right amounts. This contributes to the protection of your brand which is priceless for all food companies.

Brand Protection

See below real cases, and decide whether your company can afford the negative and brand tarnishing effects of food contamination, which could have easily been avoided by the use of

food-approved lubricants such as Fuchs specially formulated Cassida range.

The major categories of incidents are environmental contaminations: spills 28%, natural chemical contamination 13%, salmonella, listeria etc. 11%, physical contamination 10% Source FSA

Packaging Industry

A wide range testing series has revealed alarmingly high lubricant contaminated packaging used to sell food products. The contamination level was found to be up to sixty times higher than was deemed safe. Authorities are calling for a major re-think on how the packaging is produced.

Lubricant contamination is a constant threat in the food processing industry; even trace quantities of oil can result in damaged batches or products, and force a company to undertake a reputation and brand damaging product recall.

Animal Feeds

Where oils and greases are required for the lubrication of machinery used in the production of animal feeds there will always be a potential risk of contamination of the finished product. This may happen as a result of leaking gear boxes, hydraulic hoses and bearings etc. Ever tightening legislation to safeguard the food chain is placing greater responsibility on the manufacturer for food quality and safety. To eliminate this risk, food grade NFS H1 lubricants are required to protect your brand.

The use of Fuchs Cassida food grade lubricants – which are non-toxic, odourless, colourless and tasteless satisfies food legislation requirements and meets equipment and application criteria (see safety and approvals)…

Food and Beverage Industry

Machinery used in food and beverage processing has many moving parts requiring reliable and efficient operation. Food and beverage contamination can occur from drips off chains, hydraulic hose failure, oil leaks from seals and gearboxes and oil mist etc. This can result in food recalls which are devastating to brand protection. Using food grade lubricants will help protect against this…

“Sliced turkey products recalled” After contamination by leading food manufacturer.

“Oil in baby food found” A firm has recalled infant formula milk after it was found to be contaminated with harmful lubricants.

“Sunflower oil contaminated with mineral oil from Ukraine” Dispatched to several European countries.

“Bottled soft drink recall” Contaminated with non food grade lubricants.

“1,421,182 cases of macaroni and cheese recalled” Product contaminated with a compressed air lubricant.

…and can mean the difference between successful products on the shelves, or product recalls, legal action and the negative consequences these have on a company’s reputation and brand equity.

Don’t be one of our case studies, ring Lincol now and see how we can keep your products safe and production moving.

General Information Download

| PRODUCT | DOWNLOAD |

|---|---|

| ISO 21469 | DOWNLOAD |

| ALLERGEN STATEMENT | DOWNLOAD |

| HALAL CERTIFICATE | DOWNLOAD |

| KOSHER CERTIFICATE | DOWNLOAD |

| ENERGY AND COSTS SAVINGS | DOWNLOAD |

| APPLICATION CHART | DOWNLOAD |

Available Packs for Fluids (main standard packs)

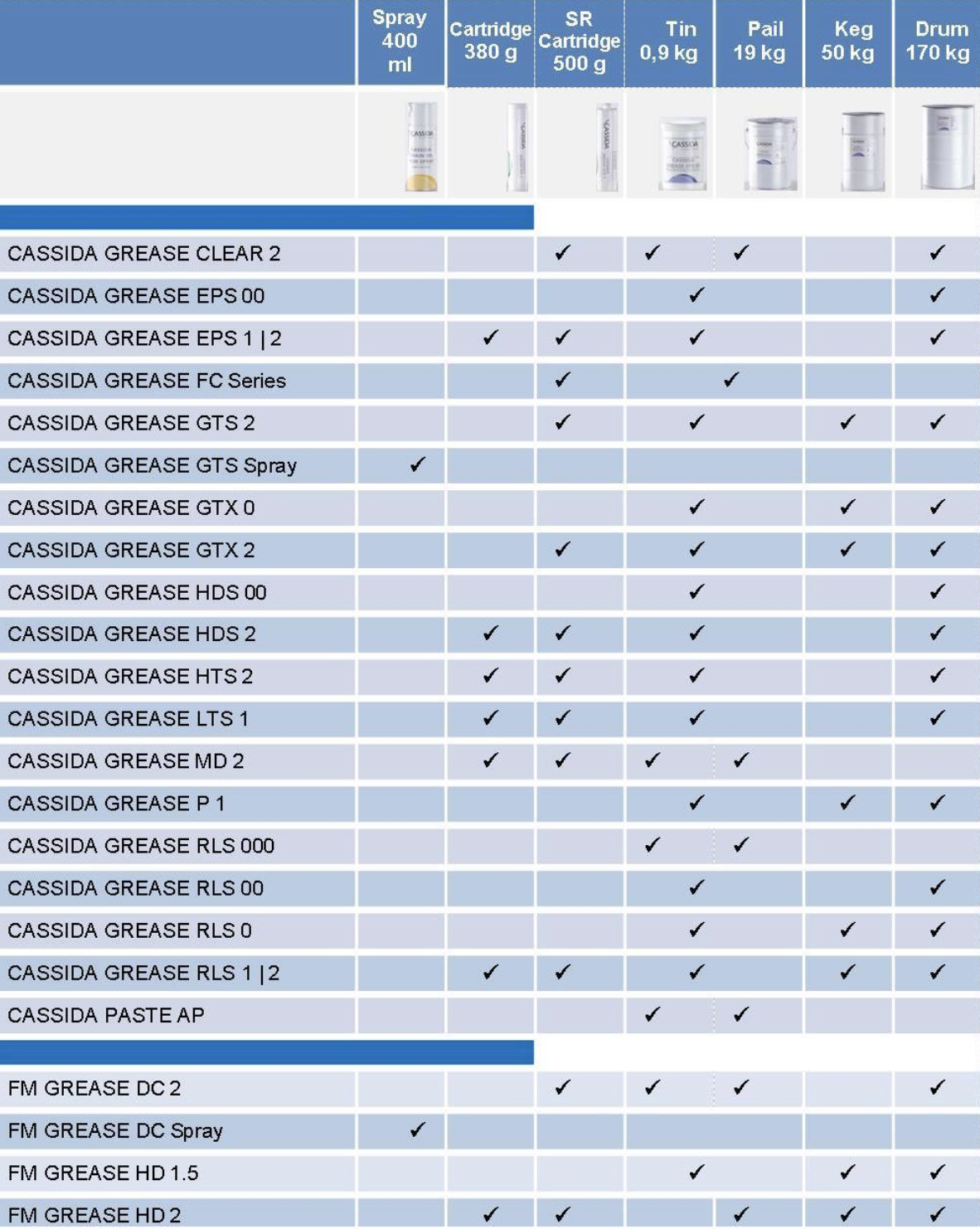

Available Packs for Greases (main standard packs)

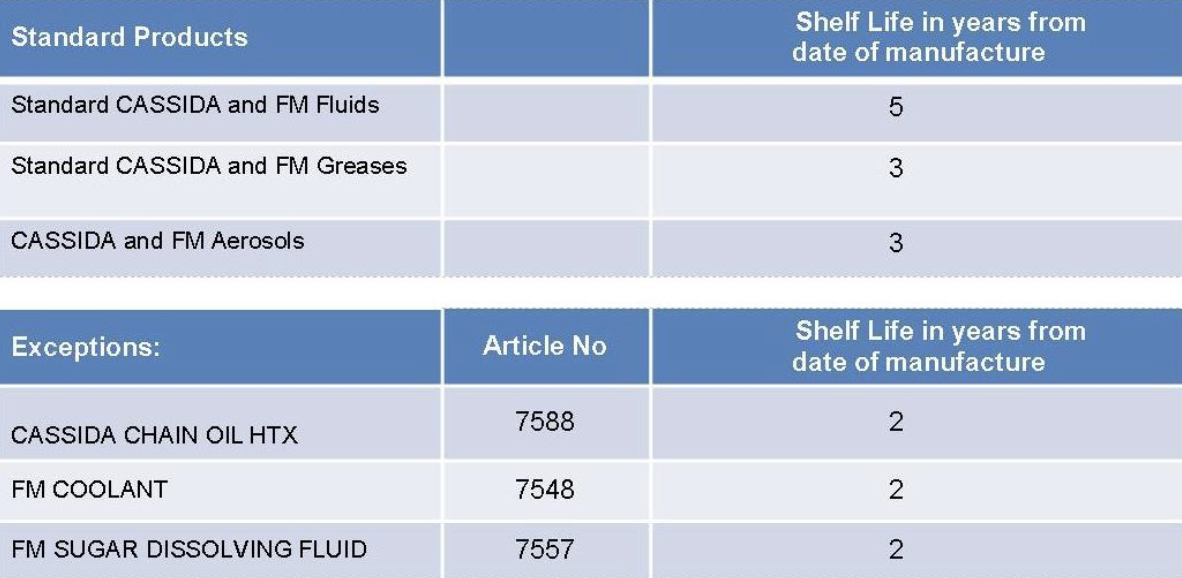

Official Product Shelf Life – Overview

Why settle for poor performance and low productivity in order to

comply with food legislation requirements?

The Fuchs Cassida range of synthetic products is capable of delivering excellent performance and satisfying changeovers from traditional, industrial or conventional white oil based food grade products.

The increased oxidation and thermal stability of these synthetic products, when compared to mineral oils, can extend oil life, oil drain intervals and filter life. They also better withstand the demands that hotter running machines place on lubricants and greases.

Not only does the Fuchs Cassida range help improve machinery uptime, it can also minimise wear which in turn will contribute effectively to maintenance cost savings.

Fuchs Cassida products have OEM approvals and recommendations from most major food processing equipment manufacturers.